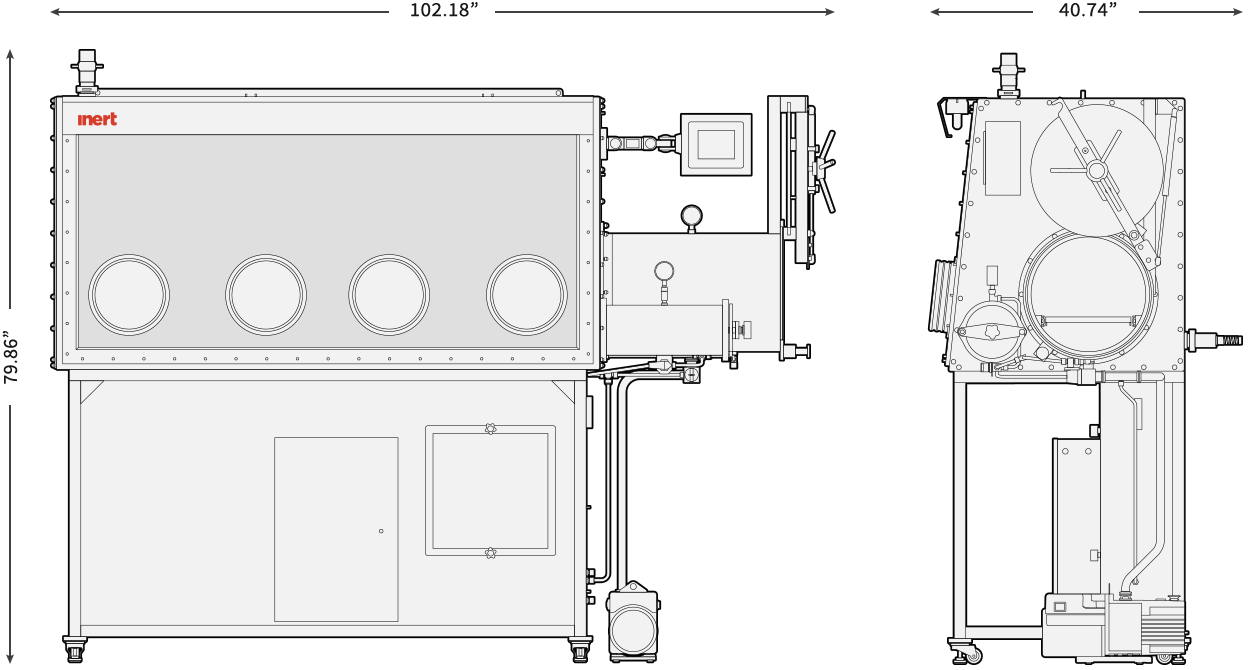

I-Lab 4GB

Glovebox System

Overview

The I-Lab line of Glovebox and Gas Management Systems are designed as an economical solution for inert research applications.

The I-Lab Gas Management Systems provide a < 1ppm O2 and H2O inert atmosphere required for a multitude of air-sensitive applications.

I-LAB Specifications

4-Glove Workstation

Hide Specifications

| Internal dimensions | 1803 mm Wide x 764 mm Deep x 897 mm High |

| External dimensions | 2595 mm Wide x 1034 mm Deep x 2024 mm High |

| Internal finish | Type 304 stainless steel, #4 |

| External surfaces | RAL 7035 |

| Wall thickness | 0.105″ (2.6 mm) |

| Feedthrough | 4 x DN 40 ISO-KF blank |

| Internal power | 1 x electrical feedthrough |

| Internal power | 1 x fuse protected 6-outlet power strip |

| Shelving | 2 x Height adjustable 304 stainless steel #4 finish. 54.1″ (1374 mm) Wide x 9.7″ (247 mm) Deep |

| Plumbing | 304 stainless steel tubing |

| Filters | 1 x inlet/1 x outlet HEPA (99.99% vs 0.3 micron MPPS) |

| Lighting | External fluorescent light |

| Power | 100-120 or 200-240 VAC 50/60 Hz 20 Amp |

Non-Modular Box Design

View Specifications

| Stand with casters and leveling feet | Leveling feet adjustability |

Large Antechamber, 15″ (381 mm) Internal Diameter x 24″ (609 mm) Internal Length

View Specifications

| Bolt | On left or right side |

| Internal finish | 304 stainless steel #4 surface finish |

| External finish | RAL 7035 |

| Internal tray | 304 stainless steel #4 surface finish |

| Tray size | 11.25″ (285 mm) Wide x 22.5″ (571 mm) Long |

| Internal/external travel | 13.9″ (353 mm) |

| Anodized aluminum doors, vertical opening with gas piston |

|

| Manual evacuate/refill valves | |

| Analog vacuum gauge | 0 to -30″ Hg |

| Leak rate | < 10-5 mbar l/s |

Small Antechamber, 6″ (152 mm) Internal Diameter x 17.3″ (441 mm) Internal Length

View Specifications

| Internal finish | 6061 anodized aluminum |

| External finish | RAL 7035 |

| Internal/external doors | 6061 anodized aluminum |

| Manual evacuate/refill valve | |

| Analog vacuum gauge | 0 to -30″ Hg |

| Leak rate | < 10-5 mbar l/s |

Polycarbonate (Abrasion Resistant) Window 3/8″ (9.5 mm) Thick

View Specifications

| Viewing size | 41.8″ (1061 mm) Wide x 30.2″ (767 mm) High |

Circular Glove Ports

View Specifications

| Black Delrin, 8″ glove port | 0.015″ (0.4 mm) thick butyl rubber gloves, hand size 9.75 |

I-Lab Gas Management System

View Specifications

| Single column gas purification system | |

| O2 and H2O purity level |

|

| O2 capacity = | 43 L |

| H2O capacity = | 1800 g |

| Automated purifier column valves | Interlocked with the blower. Blower will not run if the valves fail to open |

| Variable speed circulation blower | 120 cfm max flow rate blower |

| Max flow rate through purifier column | 60 cfm |

PLC Control System

View Specifications

| Color touch screen |

Automatic Pressure Control

View Specifications

| Automatic pressure control | (+/- 15 mbar) |

| Manual pressure control | footswitch |

Fully Automatic Regeneration Sequence

View Specifications

| Manual purge valve |

Vacuum Pump

View Specifications

| Vacuum pump | 10 cfm (17 m3/h) rotary vane pump with oil mist eliminator & oil return kit |

Integrated Oxygen Analyzer

View Specifications

| Range 0-1000 ppm |

| Zirconia sensor as standard |

| Or electrochemical sensor for solvent compatibility |

Integrated Moisture Analyzer

View Specifications

| Range 0-1000 ppm |

Overall System Leak Rate

View Specifications

| <0.05vol%/h (ISO 10648-2) |

System Gas Requirements

View Specifications

| Working gas | ³ 99.995% N2 or Ar |

| Working gas pressure | 55 psi (3.8 bar) |

| Working gas flow rate | 250 l/min |

| Regeneration gas | 3-7% H2, balance N2 or Ar |

| Regeneration gas pressure | 5-7 psi (0.3-0.5 bar) |

| Regeneration gas flow rate | 30 l/min |