Nitrogen-20 Gas Management System

24/7 operation of enclosures up to 24m3

Overview

Inert’s Nitrogen-20 quad column Gas Management Systems is equipped with four high-capacity purification columns, 0-185 CFM variable speed blower and 3-inch diameter gas loop for increased flow rate of inert gas. This Gas Management System is perfect for high throughput or large enclosures that require a < 1ppm O2 and H2O inert atmosphere.

| Regenerable Purification Coulmn | Dual Regenerable Purification Coulmn | Quad Regenerable Purification Column | Large Capacity Solvent Removal | Regenerable Large Capacity Solvent Removal | Max Enclosure Volume | |||||||||||

| Nitrogen-20 |

|

24m3 | ||||||||||||||

|

||||||||||||||||

Specifications

| Dual purifier channel allows 24/7 operation | Closed loop recirculation | |

| Piping and fittings | 304 stainless steel | |

| Circulation piping | 80 mm diameter with DN 80 ISO-KF flanges for easy connection to customer enclosure | |

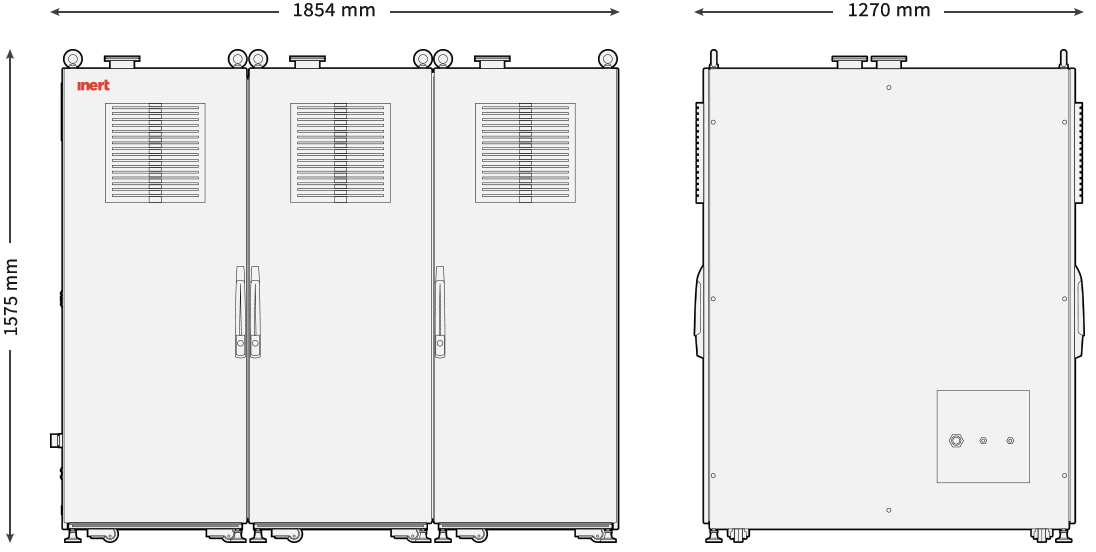

| External dimensions | 73″ (1854 mm) Wide x 50″ (1270 mm) Deep x 62″ (1575 mm) High | |

| External surfaces | RAL 7035 | |

| Internal Features | ||

| Internal cooling fans | ||

| Interior LED for maintenance | ||

| Purity Level | ||

| < 1ppm O2 and < 1ppm H2O Purity Level | ||

| O2 capacity = | 217 L per purifier column | |

| H2O capacity = | 9000 g per purifier column | |

| Column Valves | ||

| Automated purifier column valves | Interlocked with the blower. Blower will not run if the valves fail to open | |

| Circulation Blower | ||

| Variable speed circulation blower | 120 cfm max flow rate blower | |

| Max flow rate through purifier column | 60 cfm (101 m3/h) | |

| Max flow rate = | 60 cfm (101 m3/h) | |

| PLC Control | ||

| 6″ color touch screen | ||

| Trending screen | Pressure, O2 and H2O value is logged for 24 hours | |

| Pressure Control | ||

| Automatic pressure control | (+/- 15 mbar) | |

| Manual pressure control | Footswitch | |

| Regeneration Sequence | ||

| Automatic blower restart after regeneration | ||

| Purge | ||

| Purge valve | O2 level, timer or manually controlled | |

| Vacuum | ||

| Vacuum pump | 22 cfm (38 m3/h) rotary vane pump with oil mist eliminator & oil return kit | |

| Eco Mode Features | ||

| Vacuum pump timer | Energy reduction shuts pump off | |

| Automated blower speed control | O2 level adjusts blower speed | |

| Component Cycle Data | ||

| Component cycle data | Vacuum pump, column usage, blower usage | |

| System Gas Requirements | ||

| Working gas | 3 99.995% N2 | |

| Working gas pressure | 55 psi (3.8 bar) | |

| working gas flow rate | 250 l/min | |

| Regeneration gas | 3-7% H2, balance N2 | |

| Regeneration gas pressure | 5-7 psi (0.3-0.5 bar) | |

| Regeneration gas flow rate | 30 l/min | |